This is the second blog of a three-part series.

Catch up on part one: Controlling the Uncontrollable: Healthcare Supply Chain Cybersecurity.

Controlling the Uncontrollable

PART TWO: WEATHERPROOFING YOUR SUPPLY CHAIN

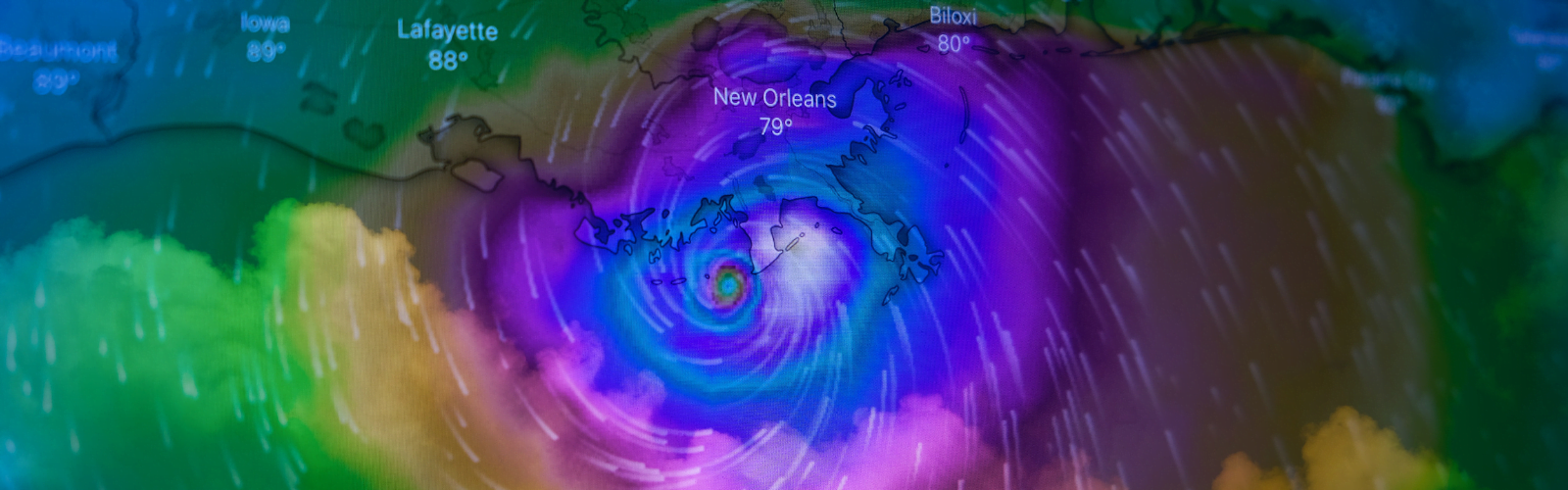

What do you do when all your well-laid plans are disrupted by the weather? Well, in the second of our three-part blog on controlling the uncontrollable, we cover how to weatherproof supply chains in healthcare. From hurricanes and wildfires to the effects of El Niño, extreme weather can have major effects on the global supply chain. Therefore, it is critical to have a plan in place.

Natural disasters and extreme weather patterns

We’ve all heard about the butterfly effect in chaos theory. In this concept, a butterfly flaps its wings in one part of the world and causes a tornado in another, showing how small causes can have large effects. Similarly, in the case of the global supply chain, natural disasters take on the role of the butterfly. With hurricanes, blizzards, and tsunamis all causing slowdowns or complete shutdowns of goods being shipped worldwide, the effects can be significant.

Due to the complexity of the healthcare supply chain, it feels the effects of natural disasters and extreme weather severely. Manufacturing and distribution issues caused by such events can lead to shortages that affect patient care. At the heart of many of these events is the El Niño climate pattern, which is responsible for causing extreme shifts in the weather and affecting nearly every step of the supply chain.

To ensure supplies are in place and care demands are met, supply chain leaders should focus on agility and resilience. Additionally, they should also be proactive in mitigating the risks they can control.

According to ASPR TRACIE, a healthcare emergency preparedness information gateway developed by HHS.gov, and a recent article in SupplyChainBrain.com, there are a number of things healthcare supply chain leaders can do both before an event occurs and in response to an actual event. These actions can help them better manage the situation.

Make like a scout and be prepared

Assess potential risks

Identify the hazards, vulnerabilities, and threats that are most likely in specific regions.

Collaborate with industry partners

Share your forecasts with your supply chain partners so they can provide greater support during a crisis. You can also build a proactive communication plan.

Use the DASH Tool

By becoming familiar with the Disaster Available Supplies in Hospital (DASH) Tool, you can estimate supplies you will need to have on hand during various types of incidents.

Diversify your supplier networks to create a safety net

Identify carriers and 3PL partners outside of your usual channels, and consider alternative mechanisms for ordering, receiving, and tracking supplies. By doing so, you can weatherproof your supply chain and set yourself up for success in the future.

Drive multi-modal efficiency

Leverage two or more transportation modes to unlock possibilities for overcoming disruptions. Not only does this help mitigate the effects of extreme weather disruptions, it can bring about additional benefits like cost reduction, lower carbon emissions, reduced fuel expenses, and enhanced security.

Identify multiple delivery locations

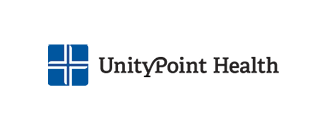

By using visibility software like VPL Inbound and Outbound Shipping, you can keep track of items sent to individual healthcare facilities or to a central warehouse. You can also use this supply chain visibility software whitepaper to discover the benefits of real-time health system supply chains.

[Pictured: VPL Inbound & Outbound Shipping Dashboard]

Define triggers and thresholds for changes to standards of care

As a last resort, determine how procedures for operating can change to weather difficult conditions.

Respond like a boss

The tsunami shut down operations. The earthquake destroyed the manufacturing plant. The fires are preventing trucks from getting into or out of the area. There’s nothing to do now but respond to natural disasters and extreme weather conditions to the best of your ability.

Alter your practices as appropriate

If you can do it without compromising care, try to decrease demand and increase the safety of substitute supplies.

Coordinate with public sector responders

They can help by engaging with distributors after your facility reports an expected lag in the availability of needed products.

Mitigate or adjust to staff shortages

Activate mutual aid agreements within your healthcare coalition of facilities not impacted by the event. Share information with patients regarding services, facility status, and any changes they should be aware of.

Embrace technology

There are a lot of things you can do to try to weatherproof your supply chain; however, nothing is as crucial as having visibility into what’s coming and where things are.

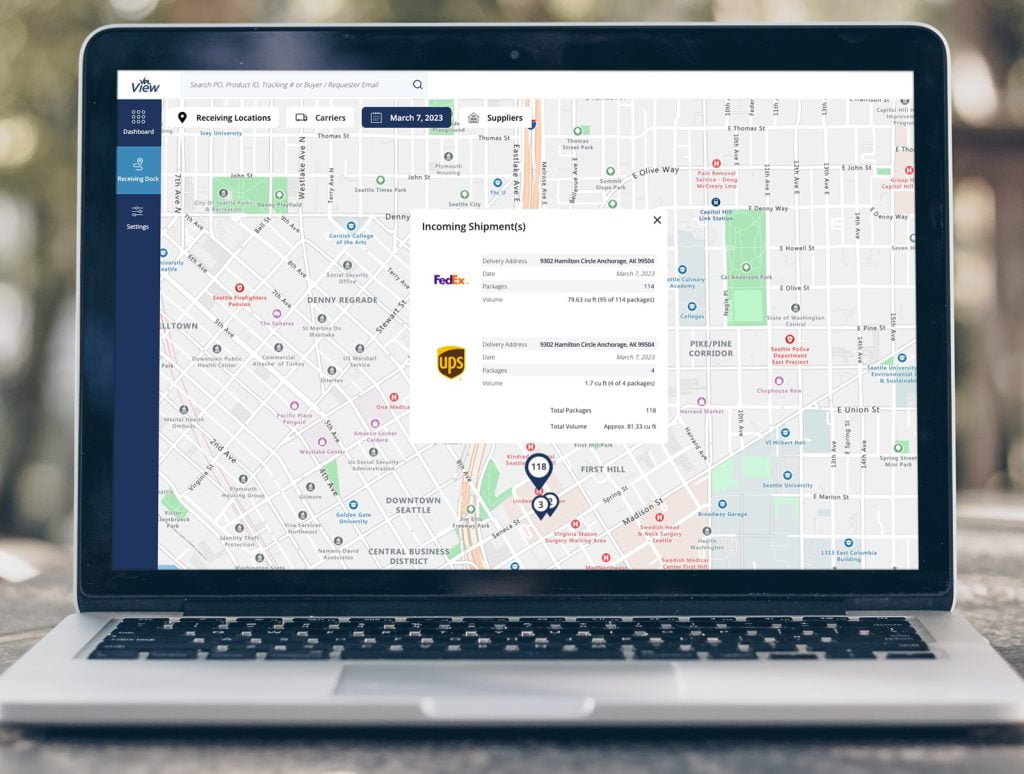

As El Niño stays with us through early next year, being able to see where products are and knowing when they will arrive will be your best guard against disruption. With this insight, you can proactively plan and make informed decisions to mitigate supply chain disruptions caused by extreme weather.

That makes this the ideal time to build your resiliency with a program like VPL’s Supply Chain Visibility Platform. VPL helps you unlock cost-saving opportunities and delivers end-to-end visibility that is crucial to thriving in spite of natural disasters.

[Pictured: VPL Supply Chain Visibility Dashboard]

By integrating this platform into your supply chain operations, you can gain real-time insights and valuable data. These insights and data allow you to respond quickly and effectively to extreme weather conditions and unexpected events.

When it comes to the weather, it’s key to embrace what you cannot change, but it is critical to change what you can—and VPL can help. By utilizing our platform and adopting weatherproofing strategies, you can strengthen your supply chain’s ability to tolerate and adapt to the impact of climate challenges, ensuring a more robust and sustainable operation overall.

Read part three: Controlling the Uncontrollable: The Impact of Political Instability on the Supply Chain.